At INVENTTECH Ltd., we offer a curated range of advanced automation and packaging solutions designed to enhance precision, efficiency, and flexibility in modern manufacturing environments.

From robotic part-handling systems for CNC machines to fully integrated pouch packaging lines, our products support seamless production flow, reduce manual labor, and increase output consistency. Each machine is built for adaptability—capable of handling varied product types, volumes, and configurations—while maintaining high repeatability and minimal downtime. Whether your needs are high-mix, low-volume, or continuous production, our equipment integrates effortlessly with existing systems to drive operational excellence.

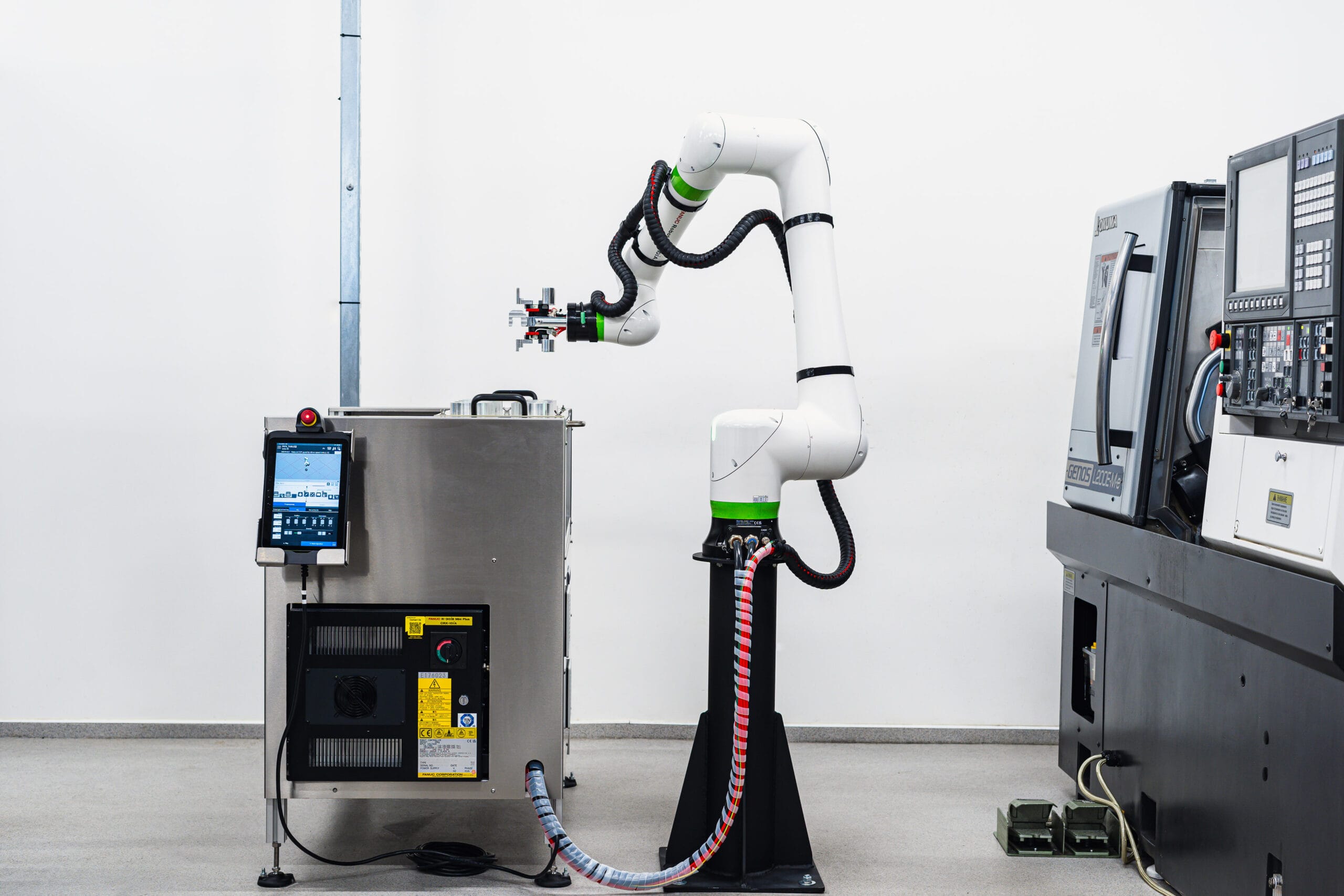

RoboTurn Assist 10

RoboTurn Assist 10 is a compact, user-friendly collaborative robot cell engineered to automate part handling for CNC machines. With a 10 kg payload, 1,418 mm reach, and repeatability of ±0.04 mm, it ensures precise, efficient, and repeatable loading and unloading of parts. Ideal for both high-mix, low-volume and continuous production environments, it offers seamless integration with existing machines.

FCM 1000

Depending on the configuration it can work as a stand-alone dosing machine or in a continuous cutting mode with the purpose of subsequent packaging of the product. Thanks to the servo drive and PLC control FCM 1000 can also work as a fully synchronized dosing module to the Horizontal Form Fill Seal – ITH 1200 or ITH 500. FCM 1000 can be equipped according to the customer requirements.

ITH 500

The packages it uses have been manufactured in advance. They can be used as stand-up pouches, glued on three or four sides. Depending on the dispenser, which the machine is equipped with, it can be used for filling bulk or liquid products. ITH 500 has been designed so that it can be reformatted easily depending on the size and shape of the package, which allows for a little downtime and great flexibility in the production process.

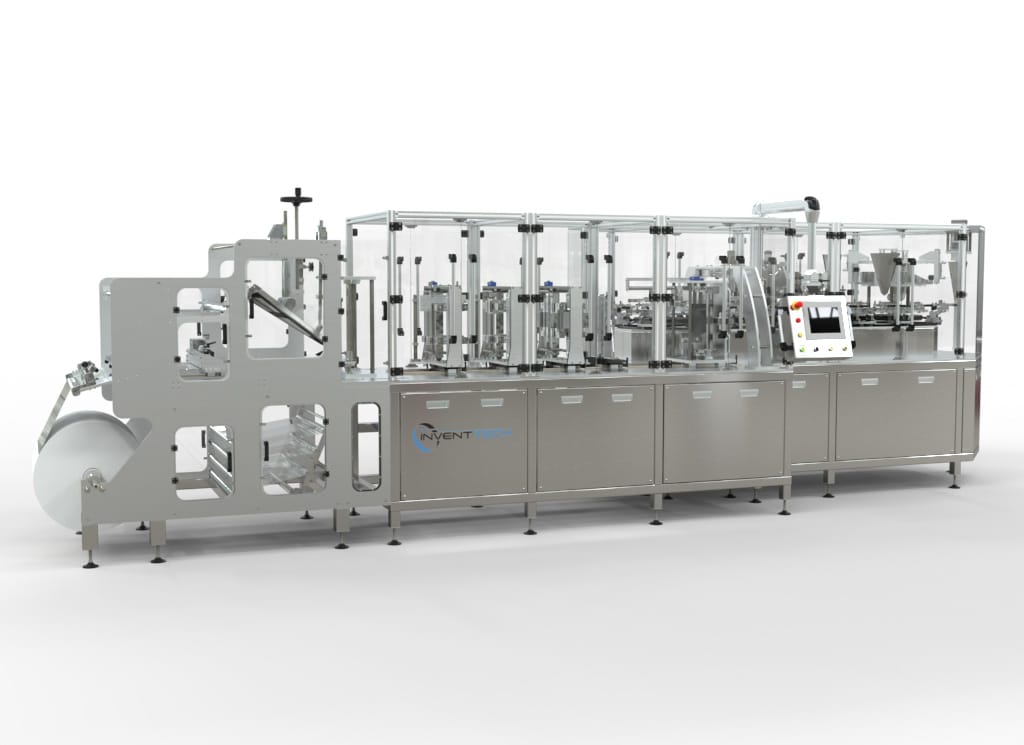

ITH 1200

The process starts by unwinding a foil roll, formation of a pouch, filling with content, which could be as diverse as possible until sealing the pouch and bringing it to a finished market-ready state. The pouches are formed automatically in preset dimensions and design and attaching a zipper is possible as well. Sealing the pouch can be carried out by temperature, ultrasound or inductively.